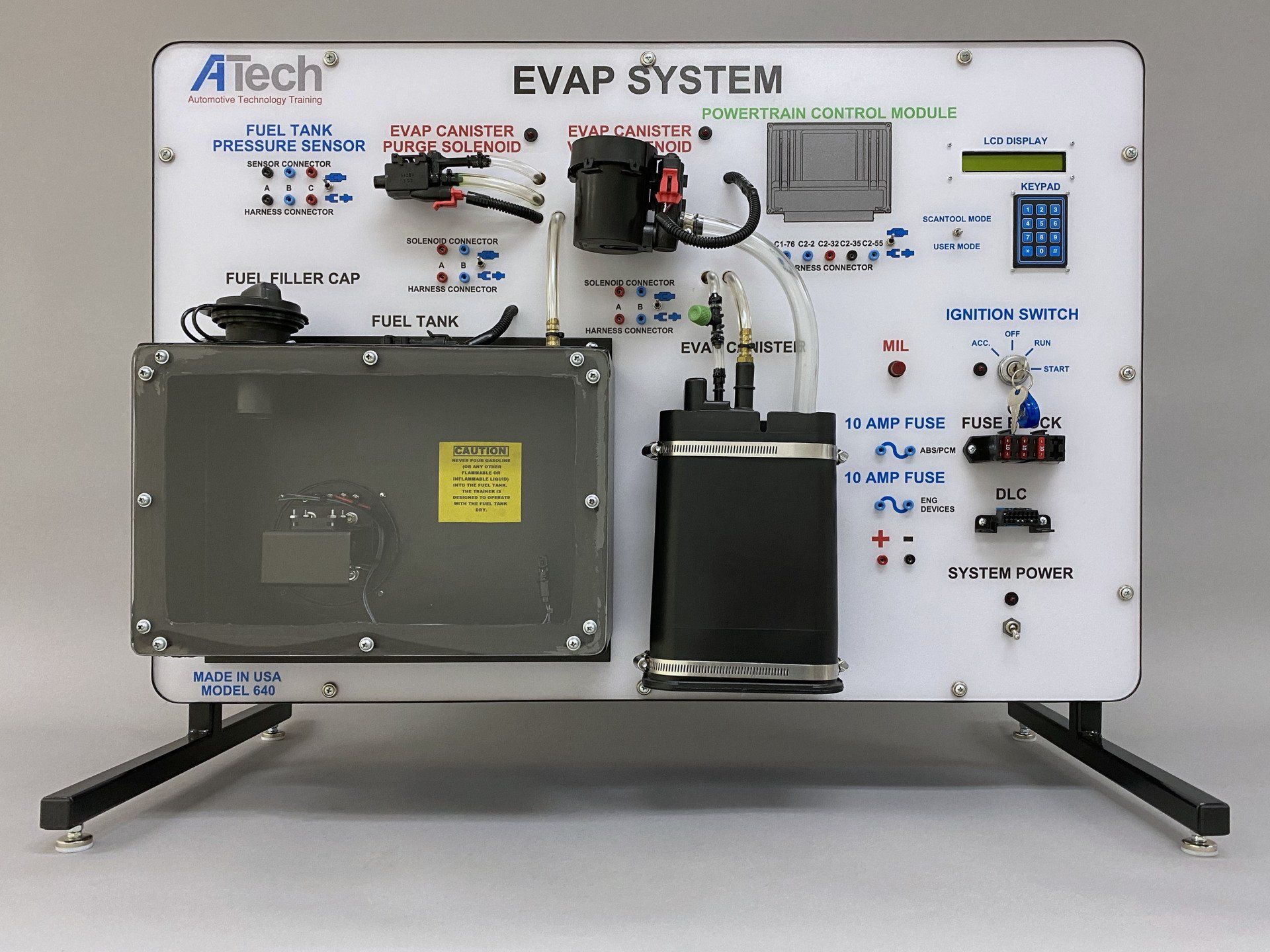

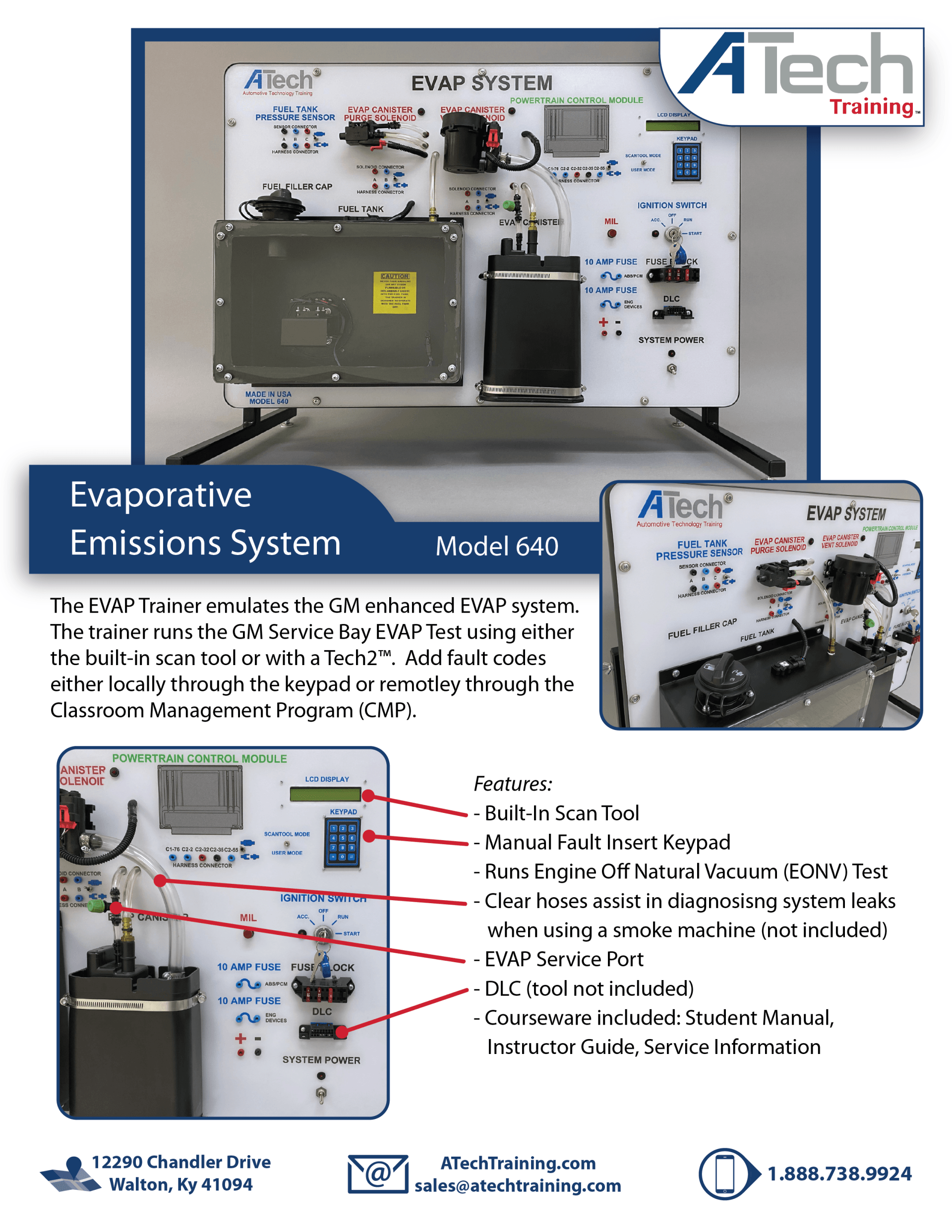

The student begins by running this test which fails and causes DTC P0442 to set as shown in Figure 1.

OBD II regulations require that EVAP system leaks as small as .020” (.51mm) be detected. How does the vehicle (or trainer) PCM determine that there’s a small EVAP system leak? From the DTC P0442 System Description for our 2003 Impala in GM SI:

“This DTC tests the evaporative emission (EVAP) system for a small leak. The control module monitors the fuel tank pressure (FTP) sensor signal to determine the vacuum decay rate. At an appropriate time, the control module turns the EVAP canister purge valve ON (open) and the EVAP vent valve ON (closed). This allows the engine to draw a vacuum on the EVAP system. At a calibrated time, or vacuum level, the control module turns the EVAP canister purge valve OFF, sealing the system and monitors the FTP sensor input in order to determine the EVAP system vacuum decay. If the control module detects a leak larger than a calibrated amount, this DTC sets.”